The TAPPI Tissue 101-Properties and Processes Course offers an introductory-level curriculum designed for anyone new to tissue.

The TAPPI Tissue 101-Properties and Processes Course offers an introductory-level curriculum designed for anyone new to tissue.You will increase your understanding of tissue properties and how they are impacted by the manufacturing process.

You can accelerate your on-the-job learning and gain a strong knowledge of ways to improve tissue performance and manufacturing efficiency.

Expand your professional network as well, through meeting the instructors and course attendees.

Course Topics:

- Introduction to tissue business and products

- Web-fiber networks and physical properties test methods

- Fibers and furnishes, stock preparation and control

- Wet-end chemistry and control

- Forming, water removal and drying processes

- Pressing fabrics, creping

- Dry-end processes and chemical additives

- Sheet and roll handling, and converting

What You Will Learn:

- Basics of tissue sheet structure and properties, and how the manufacturing process affects performance and design.

- The effect of fiber raw materials on tissue structure and properties, and how to select and apply them to achieve product goals.

- The functions of chemicals in tissue manufacture and how to apply them to increase machine/product performance.

- How each tissue machine process creates/effects tissue structure and properties.

- The most important variables controlling product quality/variability.

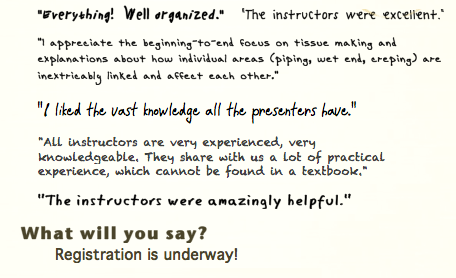

Here's what past participants said when we asked what they liked about TAPPI Tissue 101...

Who Should Attend:

- Converters and End-Users

- Technical Process Engineers

- Tissue Mill Operators

- Tissue Product Buyers

- Tissue Chemical and Equipment Suppliers

Participants with beginner- to intermediate-level experience will benefit most from this course.

Professional Development Credits

Professional Development Credits15 professional development hours or 1.5 Continuing Education Units (CEUs) are available to attendees.