| Monday, April 9th, 2018 | |||

| Special Thanks to our Gold Sponsors Stats Group

| |||

| Early Registration Delta Grand Ballroom Foyer | |||

| Exhibitor Set Up Only Delta Grand Ballroom | |||

| Welcome to Winnipeg! Free evening for attendees to settle in and see the sites in Winnipeg or relax and get ready for a great event! For what to do and what to see visit: https://www.tourismwinnipeg.com/ | |||

| Tuesday, April 10th, 2018 | |||

| Special Thanks to our Gold Sponsors Stats Group

| |||

| Registration Delta Grand Ballroom Foyer | |||

| Breakfast with Exhibitors Delta Grand Ballroom Breakfast sponsored by: | |||

| Chair's Opening Remarks & CGA Welcome Assiniboia | |||

| Host Welcome Assiniboia | |||

| Safety Awards Assiniboia | |||

| Refreshments with Exhibitors Delta Grand Ballroom Foyer | |||

| Plenary 1 – Forged In the Heart of Fire Assiniboia Spencer Beach, Motivation, Safety, Inspiration How do you embrace change when it happens? Whether it is in a corporate restructure, new initiatives, a policy role out or change from unforeseen circumstances this presentation will ignite the audience in positively impact the outcome of change. Spencer opens his heart and relives his story to share with the audience how every fearful and painful moment was to become a blessing. By using his expert story-telling and amazing sense of humor Spencer will ignite the audience to believing in the power of help. He will share why change is positive as the audience discovers his greatest lesson was Forged in the Heart of Fire. This presentation will never leave you as Spencer's messages will be applicable throughout life. | |||

| What’s Current Session Assiniboia Moderator: Patricia Kittelberger, Sales Manager, Gas Measurement Instruments | |||

| Lunch with Exhibitors Delta Grand Ballroom | |||

| Recap of Morning Session Assiniboia | |||

| Plenary 2 – Canadian Material Traceability Guidelines Assiniboia David McConkey, Manager of Operations and Safety, Canadian Gas Association Angela Scott, Manager Storage and Transmission Operations, Union Gas/Enbridge John R Anderson, Regional Manager, Emerson Automation Solutions As the Canadian federal code now includes traceability requirements, the Canadian Gas Association (CGA) initiated a task force to develop minimum guidelines to address code requirements. The task force was made up of both operators and suppliers to bring alignment on the requirements. The task force considered steel and plastic pipelines with components along with assemblies. | |||

| Move to concurrents | |||

| 2:45 pm - 3:30 pm | |||

| Engineering/Safety - Developing risk modelling tools to minimise hits to natural gas facilities Kildonan Room Jessica Ampleman, Engineer, Distribution Planning, ATCO Michael Woloski, Damage Prevention Coordinator, Gas Distribution ATCO Pipelines & Liquids Global Business Unit, ATCO Third party damage to underground facilities is unsafe, costly, a risk to system operations and preventable. According to the 2016 CGA DIRT report, 58% of hits to natural gas facilities in Alberta were due to insufficient locating and excavation practices. ATCO is developing risk modelling tools so that their Damage Prevention team can effectively contact companies and audit locates prior to the start of high risk digging activity to ensure accurate locates were made and proper exposure techniques are followed. This will allow the Damage Prevention team to focus on reducing third party damage potential at high risk excavations. | |||

| Operations/Build and Construct - CNG Filling Station at Manitoba Hydro Charleswood A Room Tanis Brako, Department Manager of Gas Apparatus Maintenance and Control, Manitoba Hydro Manitoba Hydro has recently constructed a Compressed Natural Gas (CNG) filling station for emergency response to gas outages and planned maintenance work. The presentation will provide an overview of the incident that spurred the construction of the CNG station, challenges with implementation and projects where it has already been deployed. | |||

| Integrity/Technology and Innovation - Challenges and Opportunities of Carbon Pricing for Natural Gas Distributors Charleswood B Room Trevor Mitchell, Senior Specialist Gas & Carbon Supply/Asset Optimization , Enbridge Gas Distribution Inc. Canada and Ontario have ambitious climate change goals. This is an introduction to the recently adopted cap-and-trade system in Ontario and how the carbon market is priced and traded. | |||

| (Vendors and Exhibitors Session Only) Assiniboia | |||

| Refreshments with Exhibitors Delta Grand Ballroom Foyer | |||

| Plenary 3 – Advancement in Managing Natural Gas Pipe Infrastructure Assiniboia Jim Johnston, Chief Innovation Officer, McElroy Manufacturing With Jim Johnston, from McElroy Manufacturing, we will present how industry is reacting to recent changes in standards (notably ASTM) and upcoming changes with CSA and PHMSA in the US. We will discuss how new product improvements to conventional heat fusion and electronic data capture of the fusion process with structured fusion training are changing how future projects will meet the demands of generations to come. | |||

| Closing Remarks and Evaluations Assiniboia | |||

| Reception with Exhibitors Delta Grand Ballroom | |||

| Wednesday, April 11th, 2018 | |||

| Special Thanks to our Gold Sponsors Stats Group

| |||

| Registration Delta Grand Ballroom Foyer | |||

| Breakfast with Exhibitors Delta Grand Ballroom Breakfast sponsored by: | |||

| Recap of Day One Assiniboia | |||

| Plenary 4 – Delivering Natural Gas now and for years to come, a Canadian and worldwide perspective Assiniboia Tim Egan, President, Canadian Gas Association | |||

| What's Current Part II Assiniboia Moderator: Patricia Kittelberger, Sales Manager, Gas Measurement Instruments | |||

| Refreshments and Exhibition Delta Grand Ballroom | |||

| 11:15 am - 12:00 pm | |||

| Engineering/Build and Construct - Management of infrastructure projects Kildonan Room Victor Woo, Construction Project Manager, Gaz Métro David Hudon, Construction Project Manager, Gaz Métro The coordination of gas network works with urban roadworks has always been a great challenge. Over the past years, Gaz Metro has developed a process through which they collect on a yearly basis the roadworks programs of the municipalities. This presentation will explain how this information is treated to identify some interventions required on the existing gas networks and to coordinate those works with the roadworks of the municipalities. This presentation will also explain how this process allows some of the projects on the gas network to be performed in an “integrated” manner inside the municipalities work sites in sensitive and congested urban areas. | |||

| Operations/Safety and Engineering - Leak Detection 101: The History of Leak Detection, and the Technologies that have Paved the Way for a Safer and More Efficient Natural Gas Industry Charleswood A Room Bryan Chambers, International Sales Consultant, Heath Consultants Incorporated The invention of flame ionization (FI) technology was a major revolution in gas leak detection methodology, allowing gas companies to detect small leaks in the PPM from the surface as opposed to using subsurface methods. More recently, optical and laser-based technologies have opened the door for to expanding the leak detection toolkit by making mobile and aerial surveys more feasible and cost effective. While large methane leaks have always created safety risks, the increasing focus on fugitive methane emissions has made it important to find all sources of leaks, no matter how small. This presentation will provide a brief history of leak detection and discuss the leak survey toolkit of the future. | |||

| Integrity/Technology and Innovation - Locating Failures in Buried Cathodic Protection Cables Charleswood B Room Lyndon Browne, Supervisor, Corrosion, Transmission and Distribution, ATCO Cathodic protection of buried steel pipelines protects against external corrosion and is a critical component of Pipeline Integrity Management programs. Prolonged loss of cathodic protection systems puts a pipeline at increased risk of external corrosion. Therefore, failure of buried cathodic protection cables must be remedied as soon as possible. However, depending on the failure mechanism, cable faults can be difficult to locate with accuracy. ATCO has analyzed the difficulties encountered in locating faults on buried cathodic protection cables. The analysis found that adoption of relatively new technology can greatly enhance the success rate of locating cathodic protection cable faults, thereby reducing overall cable repair costs and restoring cathodic protection sooner. | |||

| Lunch with Exhibitors Delta Grand Ballroom | |||

| 1:30 pm - 2:15 pm | |||

| Engineering/Safety - Technically Safe: How Technical Controls Create Safety for Industrial Control Systems Kildonan Room David Blanco, SCADA Security Director, AutoSol Managers have assumptions about their safety procedures that go overlooked when creating cybersecurity policies. First, that the data used for decision-making is accurate. Second, that there is only one entity exerting control over the equipment on that network. If these assumptions are false, then a company’s safety policy is undermined. This session will present the cybersecurity benefits of technical controls for industrial control systems over policy based ones as part of a safety program. | |||

| Operations/Technology and Innovation - Aerial Meter Reading Charleswood A Room Chris Blunt, Manager, Measurement and Electronics, ATCO Implementation of aerial meter reading for a utility with over 1 million service points. Focus of the discussion will be on evaluation of aerial services versus current mobile collection methods, changes required and restrictions to those changes to efficiently implement the service. | |||

| Integrity/Technology and Innovation - Improving cathodic protection test point data analysis through the use of visual tools Charleswood B Room Jonathan Landry-Bain, Engineer, Corrosion Control Program, Gaz Métro These improvements were realized by updating traditional spreadsheets. Moreover, test point data was integrated in a GIS using color coded visuals. Leak, metal loss and test point data were also integrated in the GIS to identify troubled areas. | |||

| Move to concurrents (coffee service will be provided in foyer at 3:15 pm – please proceed directly to your concurrent session). | |||

| 2:30 pm - 3:15 pm | |||

| Engineering/Build and Construct - PE Material Tracking and Traceability - ASTM F2897 Kildonan Room Mathew Desbiens, GIS Manager, AltaGas Utilities Inc. The creation of ASTM F2897 "Standard Specification for Tracking and Traceability Encoding Systems of Natural Gas Distribution Components (Pipe, Tubing, Fittings, Valves and Appurtenances)" has standardized the requirements for PE pipe/component manufacturers and natural gas utilities to collect and maintain important polyethylene asset records using barcodes. AltaGas Utilities has taken ASTM F2897 Tracking and Traceability to the next level by initiating a project to collect their new PE field assets with an integrated barcode scanner, GPS and GIS system. This session will involve a demo, utilizing barcode scanning and mobile Bluetooth technology integration, review the initiatives AUI has developed and will also review some of the challenges and successes encountered thus far. | |||

| Operations/Technology and Innovation - Evolution in Dispatch Charleswood A Room Melissa Tzotzis, Work Management Dispatch Lead, Enbridge This presentation will focus on recent changes in Dispatch to help reduce overtime and demands on shift workers. We will also review changes implemented to better monitor response time and keep Dispatchers on the leading edge of technology. Over 60 thousand Emergency calls a year are managed by this group and every one of them is critical to the safety of our communities and employees. The primary responsibility of this department is to ensure crews arrive on site within the emergency threshold and complete the work safely. | |||

| Integrity/Technology and Innovation – Challenges Faced for In-line Inspections Charleswood B Room Greg Knopinski, Project Manager Major Projects, Stations & Integrity, Enbridge The objective of the Integrity Management Program (IMP) at Enbridge Gas Distribution is to reduce the risk associated with high stress steel pipelines. The IMP was developed and implemented to meet the requirements of the Pipeline Integrity Management Program mandated by the TSSA and to satisfy the CSA Z662 Annex N. In-line inspections are performed for steel pipelines operating at stress levels at or over 30% SMYS on a 7-year interval to determine the condition of these pipelines which are a part of our distribution system. There are challenges faced with retrofitting the pipeline prior to in-line inspection, designing of launcher and receiver facilities within urban settings, operationally executing inline inspections on a distribution system, and executing Integrity Digs within the prescribed timeframes as part of the Pipeline Integrity Dig program. | |||

| Refreshments with Exhibitors Delta Grand Ballroom Foyer | |||

| Plenary 5 - Technology and Innovation in the Utility Market Assiniboia Matthew Cable, Manager, Customer Technology and Innovation, Union Gas Focus on residential applications: An update on how various new technologies and partnerships are enabling Union Gas to help its residential customers become more efficient with their energy consumption. | |||

| Plenary 6 – PVDF – The New High Pressure and High Temperature Plastic Gas Pipe Assiniboia Dr. Gene Palermo, President, Palermo Plastics Pipe Consulting PVDF, a fluoropolymer, is a solid-wall thermoplastic corrosion-resistant pressure pipe that can be operated up to 1050 psig in unregulated applications, and 665 psig in regulated gas distribution applications. PVDF can be made in pipe sizes up to 24” and is joined by standard butt fusion. Dr. Gene Palermo will discuss the PPI TR-4 listings at 23°C and 140°C, the status of the ASTM standard, key properties such as SCG and RCP, cost comparisons versus steel pipe, chemical resistance to liquid hydrocarbons, and inherent UV resistance. | |||

| Reception with Exhibitors Delta Grand Ballroom | |||

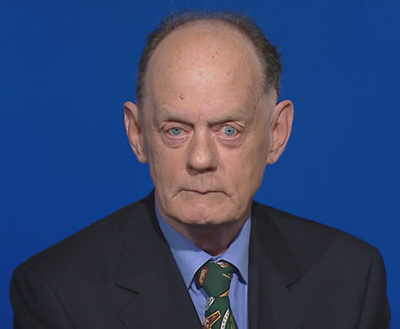

| Banquet and Guest Speaker Assiniboia Rex Murphy, Social Commentator, Editorialist & Distinct Canadian Voice The one and only Rex Murphy is a trusted face and voice across Canadian media. His intellect and biting humour strike through the heart of profound political and social issues. Currently he writes and reports for CBC’s The National and is a columnist in the National Post.

| |||

| Thursday, April 12th, 2018 | |||

| Special Thanks to our Gold Sponsors Stats Group

| |||

| Breakfast with Exhibitors Delta Grand Ballroom Breakfast sponsored by: | |||

| |||

| OEI Day Three Roundtables Kick-off panel – Standing Committee on Operations and Safety: Assiniboia Mike Shannon, Vice President, Distribution Operations, Union Gas Ltd. Kevin Cicansky, Director, Rocky Mountain Region, TransCanada Pipelines Inc. Chris MacAulay, Vice President, Engineering, Construction & Operations, Heritage Gas Russell Wintersgill, Vice President, Corporate Services, AltaGas Utilities Inc. The SCOS is the executive committee which oversees the overall CGA operations file, including all CGA operations committees and task forces. In this session, representatives of the SCOS will participate in a panel discussion examining some of the key priorities along the following four themes: • Operations - Mike Shannon - Charleswood B Room • Engineering - Kevin Cicansky - Charleswood A Room • Integrity - Chris MacAulay - St. James Room • Construction/projects - Russell Wintersgill - Kildonan Room After the panel discussion, conference participants will move into four break-out roundtable sessions structured along the same themes. 9:20 am - 9:30 am : Transition to Breakouts OEI Day Three Roundtables : The four groups will meet separately and delve deeper into their respective themes with the goals of sharing information and identifying areas of potential further exploration. Output from these sessions may feed back into CGA committee/task force activities. | |||

| A series of four sessions will be led by a subject matter expert representing the relevant CGA Committee and will have the following structure: Assiniboia 1. Welcome and overview 2. Kick-off discussion 3. Roundtable discussion 4. Targeted discussion | |||

| Exhibitor Tear Down Delta Grand Ballroom | |||

| Refreshments Delta Grand Ballroom Foyer | |||

| Continuation of breakout sessions Assiniboia 5. Identification of three summary points for plenary Roundtable Wrap-up 6. Wrap-up and next steps 11:30 pm - 11:40 pm : Transition to Plenary room | |||

| OEI Day Three Roundtable Wrap-up: Assiniboia Representatives from the four roundtable sessions will present three key summary points from their respective roundtables. These summary points could be a key learning, an area requiring further exploration, a topic for discussion at the next OEI, or any other notable discussion point. | |||

| Conference Closing Remarks/Announcement of the 2019 OEI Conference and Prize Draws Assiniboia | |||

| Optional Tour - Compressed Natural Gas (CNG) Facility Tour Manitoba Hydro recently constructed a CNG facility to fill mobile trailers for emergency response and maintenance activities. The tour will be an onsite review of the newly constructed facility along with the CNG trailers and decant unit. NOTE: PPE is required - Steel toe boots, hard hats, safety glasses and vests. | |||